Finally a building product

you can rely on

Send through your plans to our email for free initial pricing review to include out SIP system in your upcoming build.

Don’t have final drawings, that’s fine, we can work with a sketch with basic dimensions too.

Who are we and what are we doing on your screen?

Australian owned SIP supplier

SIP Solid is the local partner for Solcraft Australia Pty Ltd & Solcraft Ltd (Poland).

We manage sales of the various Solcraft SIP products in Victoria, South Australia, and Tasmania.

Solcraft is currently manufactured in Poland at a state of the art factory that has been operating since 2011 and has plans to commence local manufacturing in the future.

Solcraft has developed a pioneering manufacturing process to reduce the costs of manufacturing SIPs, which enables them to provide a high quality product, for the lowest price in the world.

What is a SIP?

A Structurally Insulated Panel is an engineered product that works in the same way as a steel beam to provide amazing strength in a limited size.

The added bonus to the strength of most SIPs, are the thermal performance that is gained by using a core material with very high thermal resistance.

SIPs also allow much faster construction to occur as the entire floor, wall, and roof can be assembled in a matter of days for standard sized home and then easily protected from the weather.

No more mouldy timber frames left on site for months at a time…

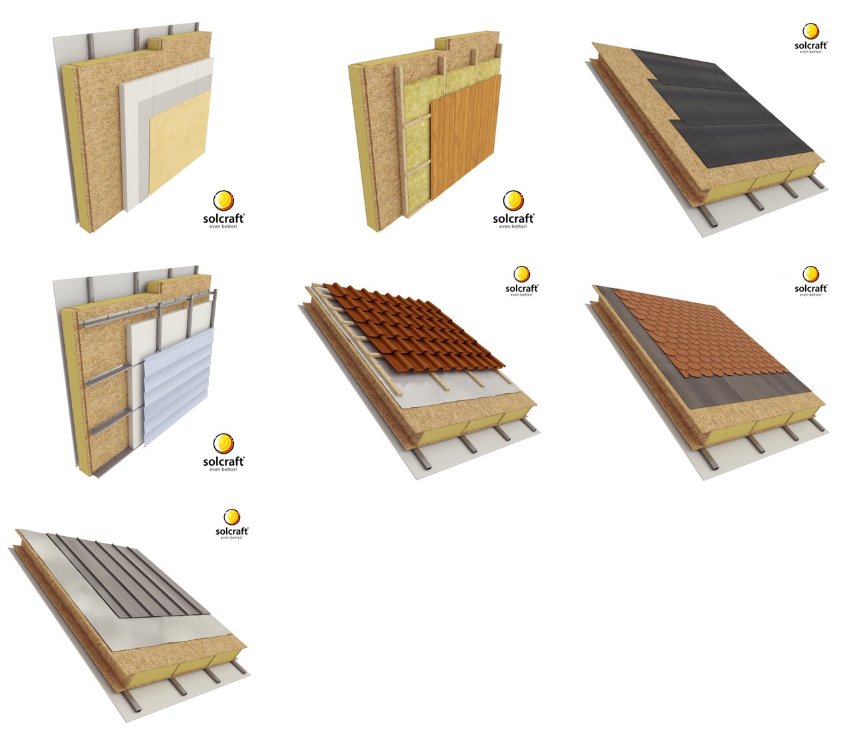

What type of SIPs are available?

We have been working with multiple SIP suppliers for nearly 5 years and have tried all of the current systems available.

Almost all of the SIP products in the market will perform far better than current building standards require and simple insulated timber frame.

The common benefit to most SIP products is the core material is far more resistant to thermal transfer than bulk insulation which is commonly used.

There are a few different core types;

EPS – Expanded Polystyrene is probably the most common but also the most problematic. This is one of the materials caught up in the combustible cladding disaster.

GPS – Graphene Polystyrene is a higher performing core (about 30% better than EPS) and has some added bonus with a high resistance to fire than EPS.

PU – Polyurethane is the best of the bunch with the highest thermal resistance and greatest ability to withstand fire.

Others – There are other core materials in the market that include, hemp, mycelium, rockwool, with more being developed. These other core types are generally at an earlier stage of development and either not yet available or not tested for long term durability.

EPS, GPS, and PU are all products that have been in use for at least 25+ years in SIP products.

Why is thermal resistance important?

If you think about what you want from your home, most people will say to be comfortable.

Temperature is the simplest way to gauge comfort -> Too hot or too cold = not comfortable.

By using building products with high resistance to thermal transfer, we can slow down the speed of transfer from hot to cold and maintain comfortable interior temperatures.

This thermal image shows the timber frame viewed from the outside of a heated building. You can see the timber studs because they are allowing the heat from inside to escape faster than the insulation between them.

What does this mean for my home?

Knowledge gives you choice.

Code built housing has been described as being as good as a leaky tent.

https://www.abc.net.au/news/2022-07-15/why-are-australian-homes-so-cold/101227308

By understanding the thermal resistance value of the different products that are used to construct the external envelope of a building, we can ensure that we remove these thermal bridges to improve the overall thermal performance of the building.

Here’s a basic chart that displays the R-values for different materials at a 90mm thickness:

| Material | Thermal Resistance (R-value) (90mm thick) |

|---|---|

| Aluminium | ~0.00044 m²K/W |

| Steel | ~0.0018 m²K/W |

| Timber (softwood) | ~0.43 m²K/W |

| Traditional bulk insulation | ~2.0 m²K/W |

| EPS (Expanded Polystyrene) | ~3.2 m²K/W |

| GPS (Graphite Polystyrene) | ~4.2 m²K/W |

| Polyurethane | ~5.85 m²K/W |

What is so special about the Solcraft SIP system?

Solcraft is currently the only supplier in Australia that uses the highest performing Polyurethane core for it’s structural panels.

Solcraft also uses high-performance spline details to remove timber splines that are used in most other systems. This removes the thermal bridge that occurs in every panel joint and can make obtaining Passive House compliance more challenging.

Solcraft also uses the thickest OSB face sheet on the market at 15mm. This is a 25% increase on all competitors and gives more strength to the system, allowing greater roof and floor spans.

We can still have timber integrated into the system at the top and bottom of the wall, and sometimes it is required for larger spans.

Simply put, Solcraft is the strongest and best performing system on available, and it’s why we have partnered with them to supply it to the Australian market.

But my house design is unique…

We can provide panel layout for ANY house design.

There are no restriction as our system is made specifically for each project.

While there are some products that are available in set dimensions, the work required to modify on site far outweighs the benefits and cost savings.

The second best benefit to the thermal performance of our system, is the install speed.

This frame was was installed in 2 days with only 4 workers and only requires a few hours of work to be water tight.